How to Repair Rising Dampness in walls of Ground Floors in Buildings Constructed without DPC? and How to Repair Efflorescence in Buildings?

Introduction

The plinth is the portion of the wall of a building immediately

above ground level to the ground floor level. This height usually ranges from 45 cm to 100 cm. Nowadays, in building construction, we provide a beam at

the lower or upper level of the plinth, called the plinth beam. It is usually

10 cm thick with at least 6 mm rods spaced at 10 cm at the top and the bottom

and 6 mm stirrups at the rate of 23 cm. (This is in addition to the grade beam

or ground beam we provide at the foundation level for isolated footings, under

reamed piles, etc.)

In all buildings, nowadays, we build a damp-proof course

(DPC) to prevent dampness from going up the walls from the foundation due to the capillary

action of groundwater. The damp-proof course can be on the plinth beam or on a

beam built separately always above the ground level. If it is built separately,

it should be at least 40 mm to 50 mm thick and should have 1:2:4 concrete with a waterproofing compound. Over this, we paint a thick layer of bitumen to prevent

water from rising from the wall from the foundation. A much cheaper way for low-cost

buildings is to put only a 1:3 cement mortar layer with bituminous paint (or a

bituminous membrane placed over it) in a portion of the wall above the ground.

This should be provided for all walls, i.e., external, and internal walls.

Thus, DPC prevents water from rising from the wall from the foundation by capillary

action. Even though in all the new buildings, nowadays, we place the DPC, in

old buildings like old assembly halls, old church buildings, and old residences,

these are absent. How we prevent moisture migration in these old buildings

where DPC has not been provided is the major problem dealt with in this article.

Methods to Rectify Dampness

The following methods are usually recommended:

1. Construct a new DPC (Note: Conventional type consists of

40 mm to 50 mm thick cement concrete in the proportion of 1:2:4 with water-proofing

compound.)

2. Pressure injection or gravity feeding of a suitable

chemical solution within the plinth (Water soluble silicon solutions are commonly

used.)

3. Pressure injection of resin mortar in boring holes

Construction of New DPC

For installing a DPC in an old building that has been

built without DPC, we cut the mortar bed joint of two brick courses above

ground level in stages of about one meter in length at a time. No two adjacent

lengths should be repaired consecutively. A new DPC with a waterproofing compound

can be inserted with the rebuilding of the removed brick course. This method is

too slow and may lead to structural settlement and cracking of walls if the

walls are weak. Hence, the methods described in the subsequent section are usually

recommended.

Method of Injection of Chemicals (Silicon)

Another method of repair is the injection of chemicals as a

liquid. The most common method used for placing DPC is based on injecting water-soluble

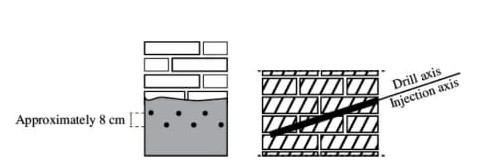

silicon (which has the moisture-resisting property) into the brickwork, as

shown in Figure below.

Pressure injections of chemicals

Note:

Silicon paints are the ones usually used for external waterproof painting and

to prevent rainwater from seeping into walls and wetting the exterior walls. We

introduce the chemicals by one of the following methods:

1. Pressure injection

2. Gravity feed

Pressure Injection

Old plasterwork etc. on the surface of the wall is

removed along the length of the wall, at least 30 cm (3 to 4 brick courses

above the ground. Holes of 12 mm diameter are bored into two-thirds the width of

masonry at approximately 150 mm horizontal intervals. These holes should be

slightly inclined downwards. The chemical solution such as polyurethane

injection resin or gel is injected by a pressure pump until it extrudes from

the masonry. We usually use high-pressure injection (0.3 MPa to 0.7 MPa) for

solvent-based solutions and low-pressure injection (0.1 MPa to 0.3 MPa) for

water-based solutions. The holes are finally closed with waterproof mortar.

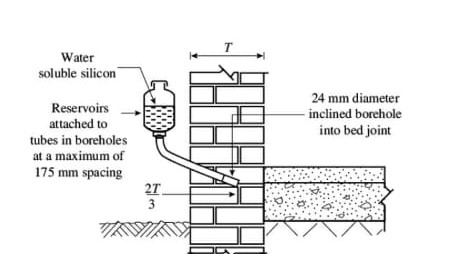

Gravity Feed

A simpler gravity feed method can also be used to treat the rising dampness (Figure below) For this method, we use larger holes having 25 mm diameter. Chemicals such as dilute silicon are transfused from the containers with feed tubes inserted into the holes. Then, the liquid is allowed to flow till the masonry gets saturated.

Figure: Gravity infusion of silicon in solution.

An alternate solution is to freeze the chemicals into

pellets and place them in the holes. They melt and disperse into the masonry.

It is to be continued till the wall section gets saturated. The holes are

finally closed with waterproof mortars.

Pressure Injection of Resin

Mortar

Another method is to inject a special mortar. It can

be used for preventing rising dampness. We bore 20 mm to 30 mm diameter holes

from both sides of the walls to a depth of three-fifth of the wall thickness.

These are 30 mm apart and inclined downwards at 20° to 30°. Flush out the drill

holes and inject the special mortar from the base of the hole upwards using hand

operated caulking gun. This mortar is composed of special cement mortars

containing styrene-butadiene resin (SBR) or epoxy resin, mixed according to the

instructions given by the manufacturers. This resin hardens to an impervious

layer and prevents the migration of moisture.

Efflorescence in Walls of

Buildings

Efflorescence is different from rising dampness. Efflorescence

is the formation of the white crystalline substance that appears on brick

walls surfaces due to salt in the brick or sand or the water used in its construction.

When the walls get wet and then, dry out, the dissolved salts come to the

surface through the pores. The salts can also absorb water from the atmosphere

and form ugly patches on the wall. Usually, efflorescence can appear above the

floor or below the roof or other places of the building where the wall can

become moist by capillary action or leakage of water.

Measures should be taken during the construction of walls so

that there will be no salts present in the materials used. We should also

provide a damp-proof course (DPC) that prevents moisture from going up the walls. Many

old buildings do not have the DPC. Similarly, rainwater should not be allowed

to moisten the walls.

Our problem is now the maintenance of a wall with

efflorescence while retaining a good shape. For this, we should prevent the

water from entering the brickwork. If the salts have already been deposited on the

surface of the wall due to past negligence, we should first remove the plaster

and scrub the surface with a brush to clean the surface of the salts. Then, we

may clean the wall with a solution of mild hydrochloric acid (1 part of acid +

5 parts of clean water). The surface is then thoroughly cleaned with a wet

brush and then, plastered, and dried. No dampness due to rainwater from nearby storage tanks or leakage of the water supply or drainage system should

wet the wall again so that the salts present inside are not brought to the

surface.

Conclusion

The rising dampness in the walls of ground floor rooms

of old buildings can be reduced considerably by injecting silicon or resin into

the walls above the ground level. It acts as a DPC for the wall. Efflorescence

can be stopped by removing the source of wetness and cleaning the deposits that

have already been deposited. No further wetting of the wall should be allowed.

while fixing dampness in the walls do we have any other material other than silicon or resin?

ReplyDeleteWindow treatments such as curtains, blinds, and shutters add privacy and style. Affordable Window Repair in Blackburn

ReplyDelete"Do you think an expansion tank is necessary for your water heater setup?" water heater replacement englewood

ReplyDelete"I recently purchased a dehumidifier for my basement, and it has made a world of difference. The air feels fresher, and I no longer have that musty smell. It's a game-changer for anyone dealing with high humidity levels." Crawl space dehumidifier installation guide

ReplyDeleteHow often should I service my home appliances? Advanced Appliance

ReplyDelete