HOW DO REPAIR OF CRACKS IN BRICKWORK IN BUILDINGS?

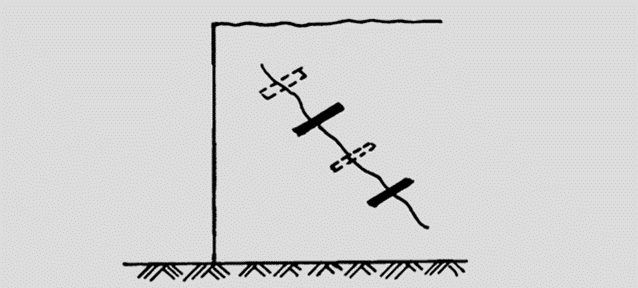

Cracks in the walls are caused by different movements caused by temperature, solution of the foundation, shrinkage and so on. From the nature of the cracks, we can infer the seat of motion. As shown in the figure below, the line normally drawn to the line of cracks intersects the seat of the settlement. Any leaks in the drains and consequent softening of the soil or other types of settlements or movements may cause these cracks.

The first step before the repair of cracks is to find the cause of the cracks and try to remedy the

cause. For example, if the cause is due

to foundation movement, it is worthwhile to proceed as follows:

(A) If there is any leakage in the drain, ditches or

manholes, it will soften the basement soil and cause different settlements. Such

leaks must be prevented.

(B) In clay soils, the foundation may be reinforced (for

example, by placing brickwork below the untreated ground level). In more severe

cases, the basement soil can be improved by lime injection or other means.

Otherwise, the foundation can be reinforced with the foundation.

Cracks in masonry due to various causes:

1. Crack due to settlement of corner, 2. Crack under RC slab due to lifting up

of corners in two-way slabs, 3. Cracks due to settlement of column C, 4. Cracks

below slab as a result of the movement due to temperature effects, 5. Crack

with larger width at the top due to heaving of the centre as occurs in black cotton

soils.

The cracks in brick walls can be repaired

by the following methods:

1. If the cracks are less than 1.5 mm in width, they are generally

filled up with putty (made at site or commercially available) and painted.

2. Cracks which are wider than 1.5 mm but are not very serious are

repaired by raking them out to about 25 mm and refilling with 1 cement, 2 lime,

9 sand mortar or preferably with other patented crack-filling compounds

available in the market. Separate types of elastic crack-filling compounds—one

suitable for small cracks in the form of a paint and another suitable for large

cracks (in the form of a semi-solid paste)—are available for filling the

cracks. These are superior to Portland cement mixes.

3. Still wider cracks have to be stitched by using reinforced mortar or

concrete stitching blocks. Thin mortar blocks can then be stuck on both sides

of the brickwork or thick concrete blocks can be inserted in the brickwork at

every 5th or 6th course as shown in Fig. below.

The thin motor blocks (11/2 to 2 brick length, 100 mm wide and 25 mm

thick) are embedded in a 6 mm reinforced core with a 1: 3 motor. After these

blocks are cured, they are inserted into the holes made on both sides during

every 5th course of brickwork (0.5 m spacing). The masonry should be drilled

only 25 to 30 mm in the brickwork for its insertion. Alternatively,

reinforcement rods are inserted in the place of these blocks, but care must be

taken to ensure that they are covered with a thick plaster coating and not in

contact with the bricks.

When repairing with thick concrete blocks, the wall should be cut to its

full depth and the RC blocks inserted at regular intervals. Blocks 1: 2: 4

Concrete one or two bricks thick, 11/2 to 2 bricks long and equal in width to

the brickwork. Two 6mm lightweight steel reinforcements are placed in the

centre of each block. Repair is about pasting cracks with these blocks every

5th or 6th lesson.

Repair

of cracks in masonry by stitching with steel rods.

If the cracks are due to minor causes, they will stabilize after a

period of time.

No comments:

Post a Comment