With the increasing cost of the burning of clay bricks, blocks made out of soil cement, cement mortar, concrete, aerated concrete, and precast stone concrete (large stone chips embedded in concrete) are becoming more and more popular. These blocks can be solid or hollow. However, the proper use of these materials, especially concrete hollow blocks, is still not understood by most users. Strict technical supervision is required in the construction of buildings with blocks, as otherwise, it will lead to heavy cracking of the walls.

Concrete

block as a material of construction is dealt with in the book on Building

Materials. We will now consider its use in masonry. IS 2185 (Parts 1 and 2)

gives the construction details and the standard sizes recommended for blocks to

be used in India.

The

standard sizes prescribed for blocks are the length of 400, 500 or 600 mm, the height

of 100 or 200 mm and width of 50, 75, 100, 150, 200, 250 or 300 mm.

We

use the larger widths for the main walls of the building and the smaller widths

for compound walls and partition walls. The commonly made sizes are 400 mm x

200 mm x 200 mm and 400 mm x 200 mm x 100 mm for main and partition walls

respectively. These are nominal dimensions including 10 mm mortar joints so

that the actual sizes can be 10 mm less. A variation of ±5 mm is allowed as

tolerance.

The

main types of cement blocks available are the following. They may be solid or

hollow.

1. Concrete blocks

2. Soil cement blocks

3. Light-weight aerated

(cellular) concrete block

4. Fly ash cement block

Notes:

1. In addition to these, we

have also hollow blocks made out of ceramics which are generally not used for

walls, but for roofs.

2. Blocks made of aerated

concrete (which are usually made solid) are called cellular blocks.

We

will restrict our study to the more commonly used concrete blocks in this article. Similar rules are applied far other blocks also. Concrete blocks are

made of concrete, not mortar. They come in many types, namely solid, hollow, or

core types. They are called "hollow" when the percentage of the void is

more than 25 per cent (clay bricks in which holes are made for less than 25 per

cent of its face area to increase the burning efficiency of the fuel are called

perforated bricks).

Hollow

blocks are those with one or more formed holes or cavities which run through

the block. Blocks with one end of these holes closed (so that it can be laid

uppermost to provide a continuous surface to spread the mortar for the next course)

are called core blocks or closed cavity blocks. Stabilized soil blocks and

cement mortar blocks are generally used for low-cost housing and

non-load-bearing walls. They have very little strength, only of the order of

1.5 N/mm2.

Hollow

concrete block construction without additional steel reinforcements performed

so poorly and led to so many fatalities during the cyclones in Sydney

(Australia) that its use without additional steel reinforcements is now

prohibited in Australia in regions prone to cyclones. Only reinforced blockwork

(for strength) with core filling (for stability) can withstand such high

cyclonic winds. This will also be true for regions of high earthquake

intensity.

Similarly, the cracking performance of soil-cement block walls in the tropics with

concrete roofs on top of the walls due to movement of the top slab has been very

poor. It is better to roof over these soil cement block walls, usually used for

low-cost construction, with AC sheets, tiles, etc., which are isolated from the

walls and produce no thermal movements on the walls.

Concrete

hollow blocks, as well as solid soil-cement and aerated concrete blocks, are

frequently used in place of brickwork. Concrete hollow blocks have the

advantages that they can be made strong by introducing steel reinforcement or

core filling.

Reinforced

blockwork is quick in construction, and its performance under all conditions

such as cyclones and earthquake loads has been good. Aerated blocks are light

and perform very well as filler blocks for multistorey framed buildings. They

can also be used to carry light loads.

To

comply with 9-inch brick sizes, hollow blocks of normal size — 450 mm x 225 mm

x 225 mm (18" x 9" x 9") — can also be produced. To build a

masonry wall of one square metre, only 10 such blocks are required against

115 clay bricks.

In

addition to the above work, it requires only 13 litres of cement mortar against over 45 litres for brickwork. It can also be built by an average bricklayer four times faster. However, experience shows that the selection of

blockwork should be more for its architectural effect than for its lower cost.

In

actual practice, plastered blockwork tends to be as expensive as brickwork but

can be faster in execution. However, the most popular size of block for

buildings is the 400 mm x 200 mm x 200 mm (nominal size) block, which can

replace 8 standard metric bricks 200 mm x 100 mm x 100 mm (nominal size). For

partition walls, we use blocks of the same length and height as used for

load-bearing walls but only 90 mm or 100 mm thick.

MUST-READ: ALL

YOU WANT TO KNOW ABOUT CONCRETE BLOCKS

What are the considerations to use hollow concrete blocks?

CONSIDERATIONS FOR THE USE OF HOLLOW CONCRETE BLOCKS

We have already seen that

we choose hollow block construction more for architectural appearance and

quickness of construction than for low cost.

The second factor that

needs consideration nowadays is the non-availability of good quality bricks and

the large improvement that has taken place in the quality of concrete blocks

which are being produced in India.

However, we should remember

that if blockwork is to be efficient for construction, the dimensions of rooms,

walls, etc. should fit the block size modules so that there will be a minimum

number of blocks cut and wasted.

We should also note that

full advantage blockwork will not be realized unless the complete range of

block shapes necessary for the construction is available. In addition to

regular blocks, blocks for bond beams for lintels, and blocks for pilasters

(rectangular columns in walls) should be available.

In the construction of

buildings for concealed electric wiring or for fixing of washbasins, etc.,

special arrangements should be made. Otherwise for easiness of construction

brickwork must be prescribed in such places.

Masonry construction with

solid and cellular blocks is very similar to brick masonry.

Hollow concrete block walls are constructed

in the following three different ways:

1.

Simple masonry (similar to brick) with the hollows untreated—the blocks are

laid one over the other breaking bonds in stretcher courses.

2.

Infilled hollow block masonry with plain concrete infilling.

3.

Reinforced hollow block masonry with steel reinforcement and concrete infilling

for higher strength (used for lintels, retaining walls and walls for multi-storeyed buildings).

The two important structural features to remember when

using concrete blocks are as follows:

(i)

There is an inherent weakness in these blocks for shrinkage and moisture

movement. (Hence blocks should be well cured and absorption should be less than

100%.)

(ii)

Blocks being larger in size and more brittle than bricks, the cracks due to settlements

in blockwork will be larger in width than in brickwork. Hence allowable

differential settlements should be small.

Closed

cavity blocks, in which the holes are closed at one end, ensure better load

distribution, better insulation properties in cold places and minimum wastage

of mortar in the blockwork. With open cavities in hot humid regions, the air

current set up in open holes can be considered an advantage.

BASIC STEPS IN LAYING OF CONCRETE BLOCK | LAYING

OF BLOCKS

Blocks

are laid as stretchers breaking bonds as shown in Fig below (p. 64). As already

stated, the most important thing is that concrete blocks should dry out

thoroughly before use. It requires at least 28 days under normal conditions of

normal curing. Solid and closed cavity blocks with one end closed are laid in

walls with a full mortar bed as in brickwork.

If

the walls are constructed of hollow blocks with through holes, the economy in

mortar can be made by "shell bedding" where the mortar is laid only

on a 5 mm (2 in) strip around the outer edge of the hollow block. Blocks should

not be wetted before use (as we specify for brickwork in cement mortar) as the

concrete can take up water and then shrink. Excess mortar is gently removed to

give a good appearance. The bottom layer of blocks on the foundation is always

laid on a full bed of mortar.

The

third important point to remember in hollow block construction is that the

mortar used for blockwork should not be too strong. With strong mortars, when

the wall shrinks, it tends to crack up with a few large cracks. With moderately

strong mortars, the movement results only in a number of small cracks

distributed on the whole length of the wall which will not be noticeable. If

cement mortar is to be used, a mix 1:5 with a plasticizer is found to be

sufficient. 1:1:6 or 1:2:9 cement lime plaster is preferable to pure

cement plaster. The ideal mortar should have the same density, strength and

drying shrinkage as the block.

Pointing

is usually done as in exposed brickwork. The longer the pointing tool, the

smoother and better the joint results. The fresh joint is left for an hour to

set, and then it is worked on for pointing.

Should hollow blocks be filled with

concrete?

HOLLOW CONCRETE BLOCKS WITH CONCRETE INFILLING

Hollow

concrete blocks (especially those with two through holes) form continuous

vertical holes when placed with proper bonding one over the other. They are

ideal for concrete filling, as these holes can be completely or partly filled

with in-situ concrete as the blockwork proceeds. Mixes with large size

aggregates can be used for this purpose. This will add greater strength to the

walls. Tests show that filling hollow blocks with plain concrete will give

basic strength approximately halfway between these unfilled blocks and

solid blocks with the same quality of concrete.

WHAT IS REINFORCED CONCRETE HOLLOW BLOCK

MASONRY?

The

vertical holes in conventional block construction can accommodate steel

reinforcement and thus be made of reinforced concrete construction when infilled.

Similarly, special blocks can accommodate horizontal reinforcements so that

horizontal beams such as lintels and horizontal strengthened reinforced

concrete bands can be built up with these blocks (see bond beams described

below). Such construction is known as reinforced concrete hollow block masonry

construction. ACI standard 531-581 and its commentary give valuable information

for the design and construction of such works.

What are the Benefits of

using hollow blocks in construction?

SPECIAL FEATURES OF CONCRETE BLOCK MASONRY

In

addition to using fully-cured blocks and lean mortar joints, the fourth most

important feature to be incorporated in blockwork, for buildings as different

from brickwork, is the need to provide the three features, namely control

joints, band beams and joint reinforcements. Unless these are provided, block

masonry is bound to result in random cracking due to shrinkage and moisture

movements. These are briefly described further.

Control

joints. Concrete has a higher coefficient of expansion than brickwork. Control

joints are continuous joints, usually vertical, built into concrete block

masonry walls for controlling thermal movements. They should be located at the change of sections in the form of vertical mortar joints to minimize the cutting of

units. They can be shrinkage joints and expansion joints. The shrinkage joints

are continuous vertical joints of approximately 18 mm (3/4 inch). These joints are

later raked and caulked (filled in). Expansion joints are located at a spacing of

45 to 60 m in suitable locations. These are filled with joint fillers which are

compressible materials that close the gap but allow movement.

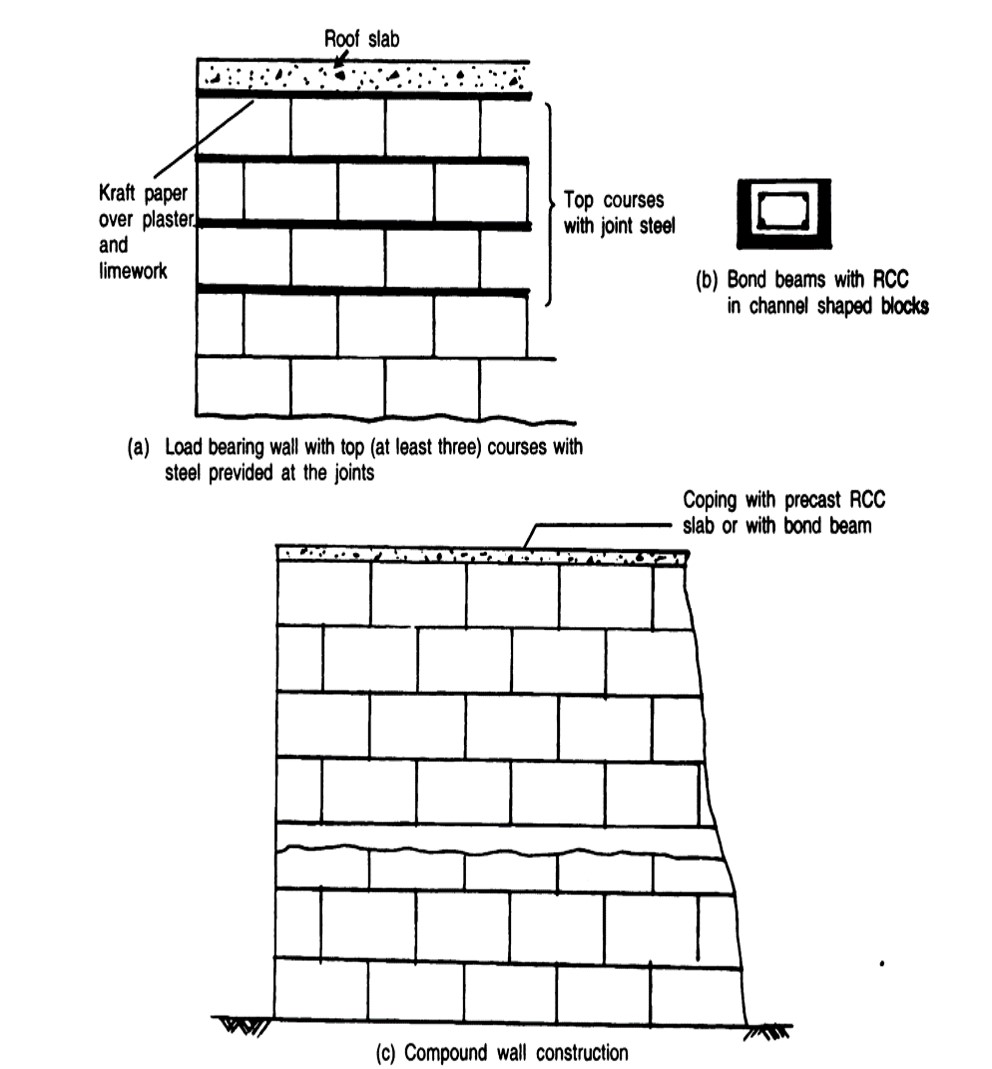

Bond

beams. Bond beams are beams such as lintels that are to be provided on top of

openings or on top of walls without top loads such as compound walls. It is

usually a reinforced masonry course, which is constructed out of specially

channel-shaped units which are filled with concrete and reinforced Fif below. It

usually serves as a structural element and as a means of crack control on top

of openings.

For

lintels, the reinforcement usually consists of at least two 12 mm bars placed

at the top and bottom. For crack control, they are made discontinuous at

control joints. Where continuity is required for structural reasons, a dummy

joint should be given to control the location of the probable crack.

Joint

reinforcement. Horizontal joint reinforcements in the form of a minimum of two No. 9

gauge wires at intervals can be used as in reinforced brickwork for crack

control. They are expensive and are not generally provided. However, when used

as load-bearing walls with RCC slabs resting on the walls, the top three

courses at least should be provided with joint reinforcement as shown in Fig

below.

Is blockwork suggested for a compound

wall?

Compound Walls In Blockwork

Unplastered concrete blockwork which is cheaper than plastered brickwork is used nowadays extensively for constructing compound walls as shown in Fig. below. There are many variations in the construction of these walls. One of the popular methods of construction is to use under-reamed piles at convenient intervals of 3 to 4 m with grade beams on top of the piles and the blockwork built on top of the grade beams.

Vertical

reinforcements can be embedded in the hollow of the block at regular intervals

from the under-reamed piles, thus strengthening the wall along its length

giving lateral resistance to wing loads or earth pressure. The top of these

walls should be finished with a coping cast in a channel-shaped block laid on

tops such as 225 mm thick lightly reinforced precast or cast in place slab over

a closed cavity block laid as the top layer or a bond beam.

CONCLUSION

Concrete

blocks are commonly used in place of clay bricks resulting in a reduction in

cement mortar and also increasing the speed of construction. As manufacturing

clay bricks require good soil and high energy, it is also more environmentally

friendly. However, there are many special points to be taken care of in good

blockwork masonry as compared to brick masonry. They have been briefly

described in this article.

Can I use concrete blocks instead of engineering bricks?

YES

Which is a better hollow block or solid block?

Hollow blocks are lighter in weight, thus reducing the dead load on the structure, so steel consumption per square foot is lower when solid blocks are applied to masonry walls. The production cost of a hollow block per unit is lower because the raw materials consumed per volume of the same volume are less compared to a solid block.

Are hollow blocks good for building?

It offers high dimensional accuracy and stable finish, making it an excellent building material for creating load-bearing structures and partition walls. e. These hollow concrete blocks are capable of withstanding high pressures and are therefore widely used in building construction practices.

Are blocks stronger than bricks?

Concrete blocks should have a minimum compressive strength of 1,900 pounds per square inch, but the strength of many blocks exceeds this limit. If we measure the strength in psi, the concrete blocks will come out on top of the bricks. The former can withstand 3,500 PSI, while the range of bricks is found at 3,000 PSI.

Is it cheaper to build with bricks or blocks?

Yes

As the cost of clay bricks rises, alternatives like soil cement, concrete, and aerated blocks gain traction. However, using concrete hollow blocks requires careful technical supervision to prevent cracking. Standard sizes are outlined in IS 2185. Proper planning for architectural impact and structural needs is vital for successful blockwork construction.

ReplyDeleteClick Here!