Floors are the horizontal

units of a building structure which divide the building into different levels.

The purpose of separation or division is to create more accommodation within a

restricted space one above the other for different purposes, viz., to provide

support for the occupants, to allow space for furniture and equipment, etc.

Strictly, the division of vertical occupation is called floors and the exposed

top surfaces of floors are termed as floorings. But in usage, both the terms

reflect the same meaning.

Thus the floor of a

building immediately above the ground is known as the ground floor. The

construction below the ground level or the building has a basement, the floor is

termed as the basement floor. The top portion of a ceiling forms the first floor or

an upper floor. Any subsequent top portions of ceilings form upper floors.

The major problems of

ground and basement floors are dampness removal and protection from heat.

Generally, there will be no problem regarding strength and stability for ground

and basement floors as they get full support from the ground. The major

problems of upper floors are strength and stability.

FUNCTIONS OF A FLOOR

A floor consists of a sub-floor and a floor covering.

Sub-floor may be a base-course or a sub-grade. This is

required to impart strength and stability to support a floor covering and all

other super-imposed loads including live loads. Floor covering or paving or

simply as flooring is the one constructed over the sub-floor and is intended to

provide a hard, clean, smooth, impervious, durable and impressive surface to

the floor.

The functional requirements of floors, in general, are as

follows:

(i) Strength and stability

(ii) Damp prevention

(iii) Heat insulation

(iv) Sound insulation

(v) Fire resistance

(vi) Durability

SELECTION OF FLOORS

In order to select a suitable type of floor construction

in a building, certain factors have to be considered. Although certain points

may be common for ground, upper and basement floors, some distinct different

points are to be observed in certain cases.

Ground Floors

For ground floors, the selection of the type of the

wearing surface is important and the other factors which need consideration are

given below:

(i) Initial

cost

(ii) Appearance

(iii) Durability

(iv) Cleanliness

(v) Thermal

insulation

(vi) Dampness

(vii) Indentation

(viii) Noiselessness

(ix) Maintenance

(x) Fire

resistance

Upper Floors

Selection of a suitable type of construction for upper

floors of a building depend on the following main factors:

(i) Initial

cost

(ii) Floor loads

(iii) Type of

construction

(iv) Plan of the

building

(v) Function of

the building

(vi) Fire

resistance

(vii) Sound

insulation

(viii) Type of

ceiling

(ix) Wearing

surface

(x) Weight and

position of floors

Basement Floor

It is not a routine type of floor provided in every

building. It is provided for a particular type of buildings like apartments,

hotels and restaurants, cinema halls, etc. The selection of basement floors depends

on the following factors:

(i) Initial cost

(ii) Availability of ventilation

(iii) Drainage of water from the floor

(iv) Adequate safety against fire

(v) Groundwater level

TYPES OF GROUND FLOORS

As the ground floor directly rests on the ground, there

is no need for a sub-floor. In order to drain the water outside completely,

adequate drainage arrangements have to be made beneath the floor.

In normal practice, the space above the ground, up to a

height of about 25–30 cm below the plinth level, called the basement, is filled

with some inert materials like sand, gravel, crushed stone, cinder, etc. Over

this course, a damp-proof course if needed is laid. Otherwise, the floor

covering is laid directly on the uniform bed.

The materials used for ground floor construction are:

bricks, stones, concrete, hollow concrete blocks or wooden blocks.

The materials generally used for floor coverings are

bricks, concrete, terrazzo tiles, marbles, stones, mosaic, wood, etc.

Stone Floors

Usual sizes of stones of 30 cm × 30 cm, 45 cm × 45 cm or

60 cm × 60 cm with a thickness of 2–4 cm are used. Generally, square stone slabs

of the above sizes are used but the slabs can be rectangular or oblong in

shape with square edges. Stone slabs are laid on concrete bedding.

Before laying the slab a base is prepared after

excavating to the required depth and the earthen base is levelled, rammed and

watered. A layer of lime concrete of thickness 10–45 cm is spread over which

the concrete bed or sub-grade is laid.

After setting the stone floor with a slope of 1 in 40,

the mortar joints are raked out to a depth of 2 cm and flush pointed with

cement mortar of 1 : 3.

Following aspects are kept in mind while laying stone

slabs, Fig. below:

(i) To begin with two stone slabs from diagonally

opposite corners are laid. A string is stretched touching these corner slabs so

as to fix top level of the floor.

(ii) Intermediate slabs are placed from both sides

taking care that the tops of stone slabs are touching the string which ensures

the provision of proper grade.

(iii) All stone slabs should be of uniform thickness,

strength and well-drained on edges for residential and public buildings.

(iv) Width of joints between the slabs should not exceed

0.5 cm.

(v) Rough surface stone, may be used for godown, sheds,

stores, etc.

Stone

flooring

Brick Floors

This type of flooring is used in case of warehouses,

stores and godowns. This is a cheap construction and used in areas when stones

are not available but good quality bricks are available.

This flooring may be laid flat or on edge. They may be

arranged in a herringbone pattern or at right angles to the walls. Brick on edge

is preferred compared to bricks laid flat as the brick on edge is less liable

for crack under pressure because of the higher depths. The bricks, in both the

cases, are laid on ordinary mortar and pointed with cement or set in hydraulic

mortar.

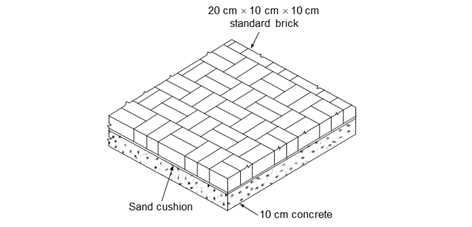

The construction of brick flooring is done as explained

below, Fig. below:

(i) An excavation of about 40 cm depth below the

intended level of the floor is made.

(ii) The earth surface is levelled, watered and well rimmed

until it is dry and hard.

(iii) Over the earth, above a sub-grade of 25 cm depth

consisting of rubble or brickbats is laid.

(iv) Over this, a 10 –15 cm thick layer of lime concrete

or lean cement concrete (1:3:6) is laid.

(v) Upon this prepared sub-grade, bricks are laid in the

desired shape.

Brick

flooring

Concrete Floors

Concrete floorings are mostly used in all residential,

commercial and public buildings. The flooring is constructed adopting either

monolithic or non-monolithic construction.

In the monolithic construction, after laying the base

course layer, immediately a concrete topping is provided. In this type of

construction, only a small thickness is needed for the wearing surface as the

bond between the base course and the wearing surface is good.

But this type of flooring has got several disadvantages

as explained below:

(i) The wearing the surface is susceptible for damage due to subsequent floor use.

(ii) As the base

course if undergoing only a small settlement immediately, there is a possibility

for hair cracks.

(iii) Repairing

the damaged top surface is difficult.

(iv) The

progress is slow as the base course has to settle.

Non-monolithic construction is sound as the wearing

surface is laid only after adequate drying of the base course. The floor finish

generally used is an ordinary concrete finish of 1:11:3 (Fig. 23.3). Under

controlled conditions, a mix of 1:2:4 ratio with carefully selected aggregates may be used.

For non-monolithic construction, the surface of the base

concrete is brushed with a stiff broom and cleaned thoroughly. The surface is

wetted and excess water removed. The floor is laid in rectangular panels not greater

than 2 × 2 m. Generally, alternate bays are concreted so as to avoid initial

shrinkages. When the concrete layer is even, the surface is rapidly compacted

by remaining or beating and screeded to a uniform level. Then trowelling is

done to give a level smooth surface. Adequate curing is done for 7 days by

spreading a layer of wet sand or special membrane may be used.

Concrete

Floors

Granolithic Floors

It is a concrete flooring

with a different type of floor finish called granolithic. Granolithic finish is

concrete made of specially selected aggregate. The thickness of the layer varies

from

1.25 to 4 cm. When it is

greater than 4 cm this may be laid monolithically or after the base concrete

has hardened.

This flooring is made with

very hard and tough quality aggregate in rich concrete of 1:1: 2. Generally, hard fine-grained granite, basalt, limestone and quartzite stones are suit-

able for coarse aggregate. In order to get a better granolithic finish, the aggregate may be crushed and used. The fine aggregates are the natural or

crushed sands with a suitable gathering. Non-slippery surfaces can be obtained

by adding suitable abrasives. In case of non-monolithic construction, the base

course may be prepared as done in concrete flooring. Granolithic flooring has

all the advantages of concrete flooring.

Terrazo

Floors

Terrazo is a special type of concrete flooring

containing marble chips as aggregates. Any designed colour and designs can be

obtained by using marble chips of different shades and colour cement.

Terrazo mix of 1: 2 or 1: 3 (1 cement to 2–3 marble

chips) is used depending on the size of marble chips. Terrazo finish is of 10

mm thick. The terrazzo finish is laid over the concrete base course (as

explained in concrete flooring) by two methods.

(i) The cement concrete base is covered uniformly by a 6

mm thick sand cushion and a tar paper is placed on this. Over this paper, a

layer of rich mortar (1 : 3) about 30 mm is placed uniformly.

(ii) A thin coat of cement is spread over the wet

concrete base. This layer is cleaned and a layer of cement mortar 12 mm thick

is spread evenly over it. When the mortar bed has hardened the terrazzo mix (1

cement : 3 marble chips) of 6 and 12 mm is laid after adding water and making the workable mix.

After curing for several days, the surface is polished

by means of a grinding machine fitted with a carborundum grinding stone disc.

During grinding the surface is kept wet and small holes or pores are filled

with a suitable cement paste matching the surface configuration. The surface is

then washed with a weak solution of soft soap in warm water. Such a finished

surface gives a pleasing appearance and a clean environment.

This type of floor is used in public buildings like

banks, hotels, offices, etc., because of its decorative appearance and

excellent wear-resisting properties.

Mosaic Floors

For the construction of this type of flooring, a hard

concrete base is laid first. When the base is wet, a 2 cm thick layer of cement

mortar (1: 2) is evenly laid. Over this layer, small pieces of broken tiles are

arranged in different patterns. After this, the inner space between tiles is

filled with coloured pieces of marble in the desired fashion.

Following this cement or coloured cement is sprinkled at

the top to get a complete floor without pores. Then the surface is rolled by a light stone roller till an even surface is obtained. After 24 hours of drying

the surface is rubbed with a pumice stone of 20 cm × 20 cm × 7 cm fitted to a

long wooden handle. This polished surface is allowed to dry for 2 weeks before

put into use.

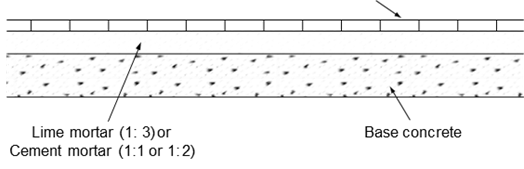

Tiled Floors

In this type of flooring tiles either of clay or cement

concrete, manufactured in different shapes, are used. A 15 cm thick layer or

lime or cement concrete is laid over the levelled ground. In order to receive

the tiles at 25 mm thick layer of lime mortar (1: 3) or cement mortar (1:1) is

laid. A cement slurry is spread over the hardened mortar. Tiles are laid flat

on this bed and a cement paste is applied on the sides. Joints are rubbed with

carborundum stone after allowing 2–3 days for setting. The entire surface is polished

with a pumice stone (Fig below).

Tiled

Floors

Tiled floorings are used in residential buildings,

hotels, offices and other public buildings. These floors can be constructed in a very short time with a pleasing appearance and good durability.

Asphalt Floors

Asphalt floorings are of two types, viz., (i) using

asphalt tiles and (ii) using mastic asphalt. Asphalt tiles are made from

asphalt, asbestos fibres and other materials and pressed under pressure.

Asphalt mastic is a mixture of fine aggregates and natural or artificial

asphalt.

Asphalt tiles are used to cover wooden or concrete

floors. These tiles are resilient, non-absorbent, moisture-proof and cheap.

They are used in schools, offices and hospitals, etc.

Asphaltic mastic can be mixed hot and laid in continuous

sheets or pressed into blocks which can be used for flooring. As an alternative, it may be mixed with oil and asbestos and applied cold. An ordinary concrete or

wood base may be used for laying this mixture.

Marble Floors

High quality marble slabs

in the required sizes and colours are available in the market. The construction

procedure is the same as that of mosaic flooring except for that marble slabs or pieces

are used instead of mosaic tiles or pieces. This type of flooring is preferred

when sanitation and cleanliness are required as in the case of hospitals,

temples, theatres and another superior type of works. Nowadays some quality

marbles are used for residential buildings also.

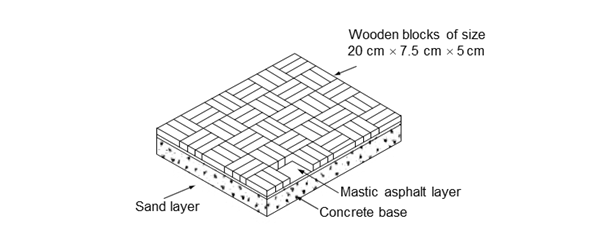

Timber Floors

Timber flooring is not generally preferred for ground

floors. If it is used as a ground floor, the prevention of dampness is most

important. Timber floorings can be provided in any one of the following

methods. Strip flooring consists of narrow and thin strips of wood joined to

each other by tongue and groove joint. Planked flooring is one type in which

wider planks are used and they are also of tongued and grooved type. Wooden

block flooring consists of small square or rectangular blocks with tongue and

groove joints, Fig. below

Timber flooring should have a concrete base or should

rest on joints spanning across dwarf walls which are constructed at suitable

intervals. For fixing the timber floors on concrete slabs, longitudinal nailing

strips are provided. Planked flooring should be laid with spaces of metals

spaced 1 mm apart temporarily for providing expansion joints. Strip flooring is

used in thickness of 2–2.5 cm and width of 6–10 cm.

TYPES OF UPPER FLOORS

Upper floors should be strong to take heavy loads,

should have sound insulation and fire resistance and also have a good wearing

resistance. The upper floors are generally classified based on the materials of

construction arrangement of beams and girders or materials used.

Commonly used floors are explained below.

Timber Floors

Timber floors are used only

in areas where more timber is available at a reasonable cost. Further, they are

used for residential buildings where the span is less and load on the floor is

less.

The floors may be of a single

joist, double joist or triple joist. Joists of floors should be strong enough

and not deflect too much causing any cracking of plaster of the ceiling. Further

long joists need strutting to avoid buckling. The planking consists of wooden

boards of 4 cm thickness and 10–15 cm wide. The figure below shows the details of a single joist timber floor, and the details of the joist’s joint are shown

separately.

Details

of single-joint timber floor

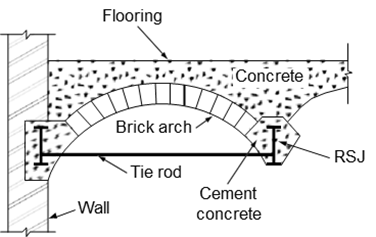

Jack Arch Brick Floors

Bricks and plain concrete can not be used directly as a flooring system without proper strengthening. Either reinforcement can be

provided or provision can be made so as to develop arch action.

Rolled steel joists (RSJ) are used to build arches so as

to form jack arch floorings. The arches have spares varying from 1.25 to 2 m

and the rise is 1/12th to 1/16th of the span. In order to accomplish the end

thrusts the rods of 2–2.5 cm are run at 2–2.75m apart as shown in Fig below.

The rods are encased in the wall along with an RSJ. The spandulus are filled

with concrete.

Brick jack arches are constructed by bringing up the

arches by laying the bricks on edges starting from the ends where the bottom of

an RSJ is concreted. Lime or cement mortar is used. After laying the brick from

ends, the key brick is introduced to set the arch action. Next layer is laid by

pushing the centring ahead. This operation is continued till the work is

completed.

Brick

jack arch floor

RCC Slab Floors

All modern buildings are invariably constructed with

reinforced cement concrete. For small spans a simple RCC slab floor is

generally suitable. For rooms, with the ratio of length of the room to its

width is greater than 1.5, slabs are designed to span along the shorter width.

That is, the main reinforcements are placed to the shorter width. The thickness

of the slab depends on the type of concrete used, the span, floor loads, etc.

These slabs are considered along with a frame then it is made monolithically

with the supporting frames (Fig. below).

RCC

slab floor

If the spans of rooms are

approximately equal then the slab is designed as a two-way slab (i.e., main

reinforcements are placed parallel to both the spans). At corners suitable

reinforcement is provided at top and bottom to take the stresses due to partial

fixity.

Reinforced concrete slabs

are laid adopting the routine mixing, laying, finishing and curing. The slab

provides a very smooth surface at the bottom and a pleasing appearance. It also

accommodates all lighting arrangements. The RCC slabs are restricted up to 4 m

span beyond which beam and slab construction has to be adopted.

The following is the construction procedure:

(i) A centring of steel or timber is erected to support

its own weight and the superimposed load.

(ii) The reinforcement is placed on the centring before

coating a thin layer (2–5 cm) of cement concrete.

(iii) The required mix of cement concrete is then

prepared and poured around the reinforcement up to the required thickness of

the slab.

(iv) The concrete is well consolidated by ramming or

using a vibrator.

(v) The concrete is cured for a minimum period of 2

weeks to attain its full strength.

(vi) After the concrete has sufficiently hardened, the

formwork is recovered.

(vii) The upper and lower surfaces of the slab are plastered

and required finish is given.

RCC Beam and Slab Floors

For larger spans and heavy loading conditions, RCC beam

and slab construction is generally resorted to. This type of construction is

commonly used for most of important buildings (Fig. below).

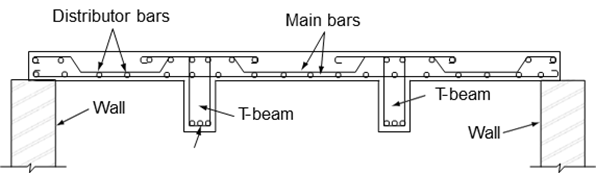

RCC T-Beam Slab Floors

In this type of floor,

beams and slabs are designed as rectangular sections and the slabs are

supported on beams. It is a monolithic construction both the beams and slabs

are cast together. The beam used in monolithic construction is called a T-beam

(i.e., a part of the slab acts as a flange of the T-beam).

The main reinforcement of

the slab runs parallel to the short span. However, some reinforcement is

provided on the other, as in RCC slab floor, as distributors. In the case of equal

spans, two-way slabs may be constructed with reinforcement provided on both

directions. Sometimes the projecting beams are covered by providing a false

ceiling underneath it (Fig. below).

RCC

T-beam slab floor

The construction procedure is same as that of RCC slab

floor, except for the type of centring or formwork required for the floor.

Flat Slab Floors

This type of floor is called a beamless slab floor.

This flat-slab floor is directly supported on columns without any intermediate

beams. This type of floor is preferred where heavy loads are anticipated and

where there is headroom restriction. The columns supporting the floor are

invariably circular in cross-section and the tops of the column are flared or

tapered, which is called as capital. Sometimes a certain portion of the slab,

symmetrical with the column, is thickened which is called drop panel (Fig. below).

Flat

slab floor

The flat slab floors have several advantages which are

given below:

(i) As there is no projection of beam, there is no need

for an additional ceiling.

(ii) More clean headroom is available.

(iii) Better ventilation and lighting is available.

(iv) Even for heavier loads only thin slab thickness is

needed.

(v) The construction is comparatively easier.

The flat slab floors are preferred under the following

conditions:

(i) When large equal number of panels are required.

(ii) Where clear large spans are required.

(iii) Where there is a limitation in headroom.

(iv) The ratio of length to breadth of panels is to be

more than 4 : 3.

(v) The difference between the length and breadth of any

two adjacent panels should not be more than 10% of the greater of the two.

The following two types of systems of reinforcement are

in use: (i) two-way system and

(ii) four-way system.

In the two-way system of reinforcement, the

reinforcement is provided between the columns and perpendicular to the columns.

The area left is considered as supported on four sides.

In the four-way system of reinforcement, the

reinforcement is placed in four directions. That is two rows of main steel from

column to column and other two rows placed diagonally across the panel from

column to column.

Resilient Floors

Floors made from materials such as PVC, linoleum,

rubber, etc., are called resilient floors. Resilient floors are soundproof and

dust free and are used in libraries, offices, computer rooms, showrooms, etc.

The three important resilient floors are: (i) PVC (Vinyl floors), Linoleum

floor and Rubber floor, which are briefed below.

1. PVC

Floor

The material in PVC floors is the thermoplastic binder

which can be vinyl chloride poly- mer or vinyl chloride copolymer or both. The

floor covering is backed with hessian or other woven fabric. Vinyl asbestos

tiles have 40% of chrysotile asbestos fibre together with powdered mineral

fillers and pigments. The thickness of normal PVC floor coverings are 1.5, 2.0,

2.5, 3.0 and 4.00 mm and the thickness of back floor coverings come in 2.0,

2.5, 3.0, 4.0 and 5.0 mm sizes. In roll form it is

usually available in 1.0, 1.5 and 2.0 m and lengths of 10 m.

2. Linoleum

Floor

Linoleum is a covering materials generally laid over

wooden or concrete floors. Linoleum material is lubricated by mixing oxidised

linseed oil with gum, resin, pigments, wood floor, cork dust and other filler

materials. It is available as rolls of 2 or 4 m width with 2–2.5 m thick and

both in plain and printed forms. Linoleum coverings are fixed to the sub-floor

by means of suitable adhesive in order to have adequate bond and high durability.

In some cases, it is nailed at the edges.

3. Rubber

Floor

It is composed of natural rubber with various filling

compounds. As the cost of rubber is high, their type of floor is expensive.

They are produced in sheets and also in tile form. A sub-floor is essential.

Hollow Block and Rib Floors

In this type of floors, to reduce the total weight of

the floor hollow blocks of clay or concrete are used. In one type, the blocks

are placed at 10 cm apart and in this space, mild steel bars are placed (Fig. below).

Suitable flooring at top and ceiling finish are provided. In order to develop

enough bond with the concrete, the blocks are provided with rough or grooved

surface.

Hollow

block and rib floor

The structural hollow clay floor tiles should be free

from cracks and of uniform colour and texture. Projections of tiles are kept on

one of the external face of such tiles so as to facilitate the application of

plaster. The dimensions of length, 45–90 cm, width, 19–24 cm and height 70–90

mm. The weight per metre length of structural hollow clay tiles does not exceed

140 N.

Thanks! For reading the article...

SOURCE: Basic Civil Engineering

Fourth Edition

MS. Palanichamy

Vice-Chairman

Tamil Nadu State Council for Technical Education Chennai, Tamil Nadu

No comments:

Post a Comment