Rainwater harvesting is more about collecting and storing on-site recycling than allowing rain. The stored water is used for various purposes such as gardening and irrigation.

There are two ways to harvest rainwater widely, viz .;

· Surface runoff harvesting

· Roof rainwater harvesting.

This article discusses several methods for Rainwater Harvesting and its components.

1. Surface Runoff Harvesting

In urban areas, rainwater flows as surface runoff. This can be used to catch the flow and recharge the water levels by following the appropriate methods.

2. Rooftop Rainwater Harvesting

This is the method of catching rainwater where it falls. When the roof is harvested, the roof becomes waterlogged, and rainwater is collected from the roof of the house/building.

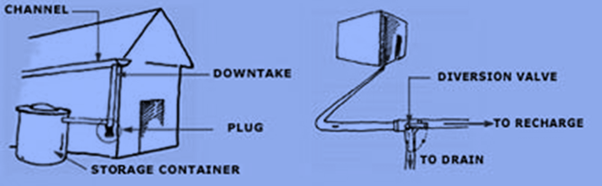

It can be stored in a tank or redirected to an artificial recharge system. This method is less expensive and more effective, and if implemented properly, can help increase the groundwater level in the area.

Components Of The Rooftop Rainwater Harvesting

A descriptive design of the essential components of a roof rainwater harvesting system is given in the typical project diagram shown in Figure 1. This system mainly consists of the following components:

Components of Rainwater Harvesting

1. Catchment is a surface that receives rain directly is the catchment area of the rainwater harvesting system. It could be a terrace, yard, or sidewalk or unpaved open space.

The terrace can be a flat RCC / stone roof or a sloping roof. So catchment is part of it, which actually contributes to the rainwater harvesting system.

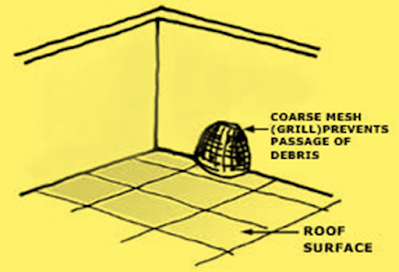

2. Coarse mesh on the roof to prevent debris from the passage

3. Gutters is Channels at the edge of the sloping roof to collect and transport rainwater to the storage tank. The gutter can be semicircular or rectangular in shape and can be made by:

· Locally available material such as folded plain galvanized iron sheet (20 to 22 lanes) with the required shapes.

· Semicircular gutters of PVC material can be made immediately by cutting these pipes into two identical semicircular ways.

· Bamboo or betel trunks are cut in half vertically.

The size of the gutter should be in accordance with the flow during the most intense rainfall. It is advisable to overdo them 10 to 15 percent.

Gutters need to be supported so that they do not overflow or fall off when loaded with water. How gutters are arranged depends on the construction of the house; iron or wooden brackets can be fixed to the walls, but in the case of houses with wider eaves, some method of attaching the rafters is required.

4. Conduits (Transportation) - Rainwater carried from the roof to the storage/harvesting system by water pipes. Pipes are made of Any material such as UV water pipes (polyvinyl chloride (PVC) or galvanized iron (GI)) which must have the required capacity of the conduits.

Water coming from sloping roofs can be captured by building pipes and under the pipe. At the bases, all drains should have wire mesh at the mouth to control floating material.

The Following table gives the idea about the diameter of pipe required for draining out rainwater based on Rainfall intensity and roof area:

SIZING OF RAINWATER PIPE FOR ROOF DRAINAGE

Diameter Of pipe (mm) | Average rate of rainfall in mm/h | |||||

50 | 75 | 100 | 125 | 150 | 200 | |

50 | 13.4 | 8.9 | 6.6 | 5.3 | 4.4 | 3.3 |

65 | 24.1 | 16.0 | 12.0 | 9.6 | 8.0 | 6.0 |

75 | 40.8 | 27.0 | 20.4 | 16.3 | 13.6 | 10.2 |

100 | 85.4 | 57.0 | 42.7 | 34.2 | 28.5 | 21.3 |

125 | - | - | 80.5 | 64.3 | 53.5 | 40.0 |

150 | - | - | - | - | 83.6 | 62.7 |

mm/ h - millimeters per hour; m - meters

Source: National Building Code

5. First-flushing device is a valve that ensures that the first spell of the rain is flushed out and does not enter the system. This should be done because the first spell of rain contains a relatively large amount of contaminants from the air and catchment surface.

6. Filter

There are always some doubts about rainwater harvesting on the roof because it is suspected that rainwater may contaminate groundwater. This fear is remotely likely to be realized if the proper filtration mechanism is not followed.

Second, all care must be taken to ensure that underground sewers are not punctured and that no leaks occur nearby.

Filters are used for water filtration to effectively remove turbidity, discolouration and germs. After the first cleaning of the shower, the water should go through the filters.

A gravel, sand and ‘netlon’ mesh filter is designed and placed on top of the storage tank. This filter is very important in keeping the rainwater in the storage tank clean. It removes silt, dust, leaves and other organic matter from entering the storage tank.

The filter media should be cleaned daily after each rain event. Clogged filters prevent rainwater from entering the storage tank easily, and the filter overflows. The sand or gravel media should be taken out and washed before being transferred to the filter.

There are different types of filters in practice, but the basic function is to purify the water. Different types of filters are described in the following section:

A. Sand gravel filter

These are commonly used filters, built of brick masonry and filled with pebbles, gravel and sand. Each layer should be separated by wire mesh.

B. Charcoal filter

Charcoal filters can be made in-situ or on drums. Pebbles, gravel, sand and charcoal should fill the drum or chamber as shown in the picture. Each layer must be separated by a wire mesh. A thin layer of charcoal is used to absorb the odor if present.

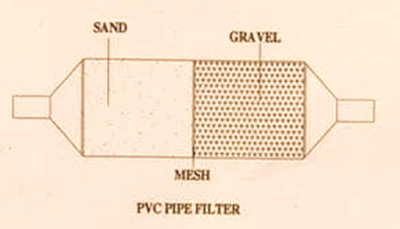

C. PVC – Pipe filter

The filter can be made of 1 to 1.20 m long PVC pipe; The diameter of the pipe depends on the area of the roof. Dia of pipe 6” is enough for 1500 sqft. 8-inch dia pipe is used on roofs of more than 1500 sqft. The pipe is divided into three boxes by wire mesh.

Each component should be alternately filled with gravel and sand as shown in the picture. A layer of charcoal can be inserted between two layers.

Reduce the amount needed to connect the inlet and outlet at both ends of the filter. This filter can be placed horizontally or vertically on the system. A projected tube filter is shown in Figure.

D. Sponge Filter

This is a simple filter made from a PVC drum with a sponge layer in the middle of the drums. It is an easy and inexpensive shaped filter that is suitable for residential units. A typical picture of the sponge filter is shown below.

7. Storage facility

There are various options depending on the shape, size and construction material of these tanks.

Shape: cylindrical, rectangular and square.

Construction Material: Reinforced cement concrete, (RCC), ferrocement, masonry, plastic (polyethene) or metal (galvanized iron) sheets are commonly used.

Tank position: Depending on the availability of space, these tanks can be built above ground, partly underground or completely above ground. Some maintenance measures such as cleaning and disinfection are required to ensure the quality of the water stored in the container.

8. Recharge structures

Rainwater can be collected in groundwater bodies through suitable structures such as dugwells, boreholes, refill trenches and refill pits.

Various refill structures can be made - some at shallow depths (e.g. refill trenches, permeable paths) promote water infiltration through the soil layer, while others carry water to deeper depths where it connects with groundwater (e.g. refill wells). In many places, existing structures such as wells, pits and tanks can be converted into reloaded structures, thus eliminating the need to rebuild any structure. Here are some commonly used reload methods:

A. Recharging of dug wells and abandoned tubewells.

In sedimentary and hard rock areas, thousands of wells have dried up or their water levels have dropped significantly. These can be recharged directly through the roof run-off. Rainwater collected on the roof of the building is diverted to a settlement or filtration tank, from which it flows into a recharge well (borewell or dug well).

If a tubewell is used for recharging, the casing (outer tube) should preferably be a perforated or perforated tube so that more surface area is available for water to circulate. Creating a borehole will increase its recharge capacity (growing means that water or air is forced into the well, forcing it to penetrate further into the soil layers around the well).

If a dug well is used for recharging, the well lining should have openings at regular intervals (weep-holes) to allow water to escape on the sides. Dug wells should be closed to prevent mosquito breeding and entry of leaves and debris. The base of the recharge wells should be dried annually to maintain intake capacity.

The quality of the water entering the recharge wells can be ensured by providing the following components in the system:

1. Filter mesh at the entrance point of rooftop drains

2. Settlement chamber

3. Filter bed

b. Settlement tank

Settlement tanks are used to remove silt and other floating contaminants from rainwater. A settlement tank is similar to a normal storage container in that it contains drainage (bringing water from the reservoir), discharge (carrying water to the recharge well) and overflow. A settlement tank can have an unpainted bottom surface.

In the event of excessive rainfall, the rate of recharging, especially borewells, will not match the rate of rainfall. In such situations, the desalination chamber retains excess water until it is soaked by the recharge structure. Thus, the solution acts as a buffer in the room system.

Any container, (masonry or concrete underground tanks, old unused tanks, prefabricated PVC or ferrocement tanks) can be used as a solution tank with adequate storage capacity.

C. Recharging of service tubewells.

In this case the roof run is not guided directly into the service pipes to avoid the possibility of groundwater contamination. Instead, the rainwater is collected in a recharge well, which is a temporary storage tank (located near the service pipe), with a borehole that is shallower than the water table. If the layer is loose, an envelope pipe should be provided to this borehole to prevent cavities in the soil. A filter chamber with sand, gravel and rocks is provided to prevent contamination.

D. Recharge pits

A recharge pit is 1.5 m to 3 m wide and 2 m to 3 m deep. The excavation pit is lined with a brick/stone wall with openings (weep-holes) at regular intervals. The upper part of the pit can be covered with a perforated cover. The design procedure is like a settlement tank.

E. Soakaways / Percolation pit

One of the easiest and most effective methods of harvesting rainwater is percolation pits usually not more than 60 x 60 x 60 cm (designed based on the expected flow described for settlement tanks), covered with pebbles or brick jelly and river sand, with perforated concrete slabs where required.

F. Recharge trenches

The recharge trench is a continuous trench dug in the ground and filled with microscopic media such as pebbles, rocks or broken bricks. A recharge trench can be 0.5 m to 1 m wide and 1 m to 1.5 m deep. The length of the recharge trench is determined by the expected run. Accumulated debris should be cleaned periodically to maintain the recharge trench intake capacity. In terms of recharge rates, recharge trenches are relatively less efficient because the soil layer at a depth of about 1.5 m is generally less permeable. In order to recharge through recharge trenches, less precautions must be taken to maintain the quality of rainfall. Running can be tapped from sidewalks and unpaved waterfalls.

G. Recharge troughs

Recharge tanks are usually placed at the entrance of a residential / corporate premises to collect runoff from a compound exit pavement or unpainted areas. These structures are similar to recharge trenches except that the excavated area is not filled by a filter. Materials. Convenient for quick recharge, the boreholes in this trench are drilled at regular intervals. In the design area, it is not necessary to combine the influence of filter materials.

This system is only capable of harvesting a certain amount of flow because of the size-related limit.

H. Modified injection well

In this method, water is not pumped into the aquifer but is allowed to pass through a filter bed, which consists of sand and gravel. The modified needle well is usually a borehole with a diameter of 500 mm, which is drilled to the desired depth depending on the geological conditions, preferably 2 to 3 m above the water table in the area. A perforated casing tube with a diameter of 200 mm is inserted into this hole. The annual gap between the borehole and the pipe is filled with gravel and formed with a compressor until clear water is supplied. A filtering mechanism is provided above to prevent suspended solids from entering the recharge tubewell.

I have read all the comments and suggestions posted by the visitors for this article are very fine, we will wait for your next article, please write something on Gutter Replacement Cost

ReplyDeleteHailing a taxi online saves so much time, especially during rush hours! Best Sxm Taxi Service In St. MArtin

ReplyDelete